Enter your VAT number here and click Verify:

Your details have been verified. VAT number registered to:

,

.

Your order will now be zero rated for VAT purposes. We reserve the right to verify these details after your order request has been made and reinstate VAT if required.

Your VAT details were not recognised or were invalid. Your VAT number must be matched to your Billing Country as specified above. This is currently specified as . You do not need to enter the country code part of your VAT number as this has already been selected in your billing address details above.

The VAT number checking service is currently offline. Please supply your VAT details within the comments or special instructions field below and we will apply a VAT discount after placing your order request.

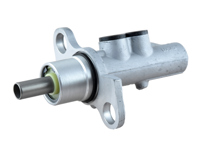

Brake Master Cylinder

Brake fluid is one of the most important fluids in a car as without it, stopping the vehicle safely would be impossible. The Brake fluid transmits the force exerted by the driver on the brake pedal onto the wheel brake.

To ensure perfect operation of the brakes, the brake fluid must be changed regularly during inspection or maintenance and tested with the correct brake fluid tester.

Brake fluid should be changed every two years.

The higher the DOT class, the higher the boiling temperature and wet boiling point. Higher DOT classes tend to allow longer maintenance intervals. The DOT standards are based on the American FMVSS-116 standard of the Department of Transportation (DOT).

Boiling Point and Viscosity

Dry Boiling Point - describes the property of the sealed new brake fluid. In this state, the brake fluid is almost anhydrous (substance containing no water). The dry boiling point is usually between 240 and 280°C.

Wet Boiling Point - determines the property of the brake fluid at the end of its life cycle, at a water content of 3.5% the fluid should be replaced. This defined wet boiling point must not be undercut.

Viscosity - describes the flow rate of the brake fluid. The lower the viscosity, the faster the brake fluid flows through the brake system, and the faster the brake signals are transmitted.

Important Notes

• Brake fluid is poisonous and a hazardous waste.

• Be careful when changing. The fluid weakens paints and plastics.

• It must not come into contact with eyes or skin. Always rinse spilled liquid with water.

• Do not pour the liquid into drinking water or mix with used oil.

• The colour of the brake fluid reveals nothing about its quality.

• Brake fluid should be stored in its original packaging and in a dry, cool and well-ventilated place.

Find out about Textar product verification here

DOT 4

Having an extremely high boiling point and lower viscosity than required, it meets and greatly exceeds regulatory standards. Also suitable for vehicles with ABS.

Vapour Lock formation

This sort of habit leaves room for the Vapour Lock, the formation of vapour bubbles due to boiling of the brake fluid that replace the normal fluid and are compressed, thereby sending the brake pedal to its fill stoke (spongy pedal). The origin is incident in the porosity of the tubes that make up the braking circuit, which in time draw moisture into the fluid, drastically reducing the boiling point. The result is a reduced braking efficiency.

Brembo Premium Brake Fluid

Brembo Premium brake fluids have a higher boiling point that exceeds the standard, thus offering superior resistance to the Vapour Lock and ensuring braking efficiency even at low temperatures. With high anti-corrosion properties and resistance to oxidation, Brembo brake fluid also allows for long-term unaltered chemical/physical characteristics of the fluid in operating circuit; therefore, preserving its integrity.

Related reference numbers

Related, superseded, cross reference or alternative numbers for comparison.

L040

The product you are viewing cross references to these numbers

Brake fluid DOT 4 LV (Low Viscosity) Textar.

Textar DOT 4 LV (Low Viscosity) is especially recommended for use in hydraulic brake and clutch systems of vehicles fitted with ESP, ABS and ASR with a high boiling point and outstanding performance at very low temperatures.

DOT 4 LV (Low Viscosity)

Dry Boiling Point ≥ 260° C

Wet Boiling Point ≥ 165° C

Viscosity at -40C < 750 mm2 /s

Brake fluid is one of the most important fluids in a car as without it, stopping the vehicle safely would be impossible. The Brake fluid transmits the force exerted by the driver on the brake pedal onto the wheel brake.

To ensure perfect operation of the brakes, the brake fluid must be changed regularly during inspection or maintenance and tested with the correct brake fluid tester.

Brake fluid should be changed every two years.

The higher the DOT class, the higher the boiling temperature and wet boiling point. Higher DOT classes tend to allow longer maintenance intervals. The DOT standards are based on the American FMVSS-116 standard of the Department of Transportation (DOT).

Boiling Point and Viscosity

Dry Boiling Point - describes the property of the sealed new brake fluid. In this state, the brake fluid is almost anhydrous (substance containing no water). The dry boiling point is usually between 240 and 280°C.

Wet Boiling Point - determines the property of the brake fluid at the end of its life cycle, at a water content of 3.5% the fluid should be replaced. This defined wet boiling point must not be undercut. <

Viscosity - describes the flow rate of the brake fluid. The lower the viscosity, the faster the brake fluid flows through the brake system, and the faster the brake signals are transmitted.

Important Notes

• Brake fluid is poisonous and a hazardous waste.

• Be careful when changing. The fluid weakens paints and plastics.

• It must not come into contact with eyes or skin. Always rinse spilled liquid with water.

• Do not pour the liquid into drinking water or mix with used oil.

• The colour of the brake fluid reveals nothing about its quality.

• Brake fluid should be stored in its original packaging and in a dry, cool and well-ventilated place.

Find out about Textar product verification here

Related reference numbers

Related, superseded, cross reference or alternative numbers for comparison.

95006

The product you are viewing cross references to these numbers

Brake fluid is one of the most important fluids in a car as without it, stopping the vehicle safely would be impossible. The Brake fluid transmits the force exerted by the driver on the brake pedal onto the wheel brake.

To ensure perfect operation of the brakes, the brake fluid must be changed regularly during inspection or maintenance and tested with the correct brake fluid tester.

Brake fluid should be changed every two years.

The higher the DOT class, the higher the boiling temperature and wet boiling point. Higher DOT classes tend to allow longer maintenance intervals. The DOT standards are based on the American FMVSS-116 standard of the Department of Transportation (DOT).

Boiling Point and Viscosity

Dry Boiling Point - describes the property of the sealed new brake fluid. In this state, the brake fluid is almost anhydrous (substance containing no water). The dry boiling point is usually between 240 and 280°C.

Wet Boiling Point - determines the property of the brake fluid at the end of its life cycle, at a water content of 3.5% the fluid should be replaced. This defined wet boiling point must not be undercut.

Viscosity - describes the flow rate of the brake fluid. The lower the viscosity, the faster the brake fluid flows through the brake system, and the faster the brake signals are transmitted.

Important Notes

• Brake fluid is poisonous and a hazardous waste.

• Be careful when changing. The fluid weakens paints and plastics.

• It must not come into contact with eyes or skin. Always rinse spilled liquid with water.

• Do not pour the liquid into drinking water or mix with used oil.

• The colour of the brake fluid reveals nothing about its quality.

• Brake fluid should be stored in its original packaging and in a dry, cool and well-ventilated place.

Find out about Textar product verification here

Related reference numbers

Related, superseded, cross reference or alternative numbers for comparison.

95002

The product you are viewing cross references to these numbers

- Porsche Boxster 987 2.7L 2005-08/08

- Porsche Boxster 987 S 3.2/3.4L 2005-08/08

- Porsche Boxster 987 MKII 2.9L 2009-12

- Porsche Boxster S 987 MKII 3.4L 2009-12

- Porsche 997 MK1 Carrera 2 3.6L 2005-08

- Porsche 997 MK1 Carrera 2S 3.8L 2005-08

- Porsche 997 MKII Carrera C2 3.6L 2009-12

- Porsche 997 MKII Carrera C2S 3.8L 2009-12

- Porsche Cayman 2.7L 987C 2006-08

- Porsche Cayman S 3.4L 987C 2005-08

- Porsche Cayman 2.9L 987C MKII 2009-12

- Porsche Cayman S / R 3.4L 987C MKII 2009-12

Fits:

Porsche 987.1 Boxster 2005-08

Porsche 987.1 Boxster 2009-12

Porsche 987C.1 Cayman 2005-08

Porsche 987C.2 Cayman 2009-12

Porsche 997.1 C2 / C2S 2005-08

Porsche 997.2 C2/ C2S 2009-12

Click 'Zoom in' for large parts diagram.

Diagram ref no 3

Related reference numbers

Related, superseded, cross reference or alternative numbers for comparison.

99907361501

The product you are viewing cross references to these numbers

- Porsche Boxster 987 2.7L 2005-08/08

- Porsche Boxster 987 MKII 2.9L 2009-12

- Porsche 997 MK1 Carrera 2 3.6L 2005-08

- Porsche Cayman 2.7L 987C 2006-08

- Porsche Cayman 2.9L 987C MKII 2009-12

- Porsche Cayman S / R 3.4L 987C MKII 2009-12

The brake master cylinder converts driver pedal input into precise hydraulic pressure that activates the brake calipers. As a genuine Porsche component, it delivers the exact pedal feel, pressure balance, and braking response intended by Porsche engineers.

Fits:

Porsche 987.1 Boxster 2005 - 2008

Porsche 987.2 Boxster 2009 - 2012

Porsche 987C.1 Cayman 2006 - 2008

Porsche 987C.2 Cayman 2009 - 2012

Porsche 997.1 Carrera 2 2005 - 2008

Diagram ref no 5

Function: When the brake pedal is pressed, the master cylinder’s internal pistons generate hydraulic pressure and distribute brake fluid evenly to the braking circuits. This ensures consistent braking force, smooth modulation, and predictable stopping power under all driving conditions.

A failing master cylinder directly impacts braking safety. Internal seal wear or cylinder fatigue can reduce hydraulic pressure, leading to poor pedal feel and longer stopping distances. Replacing the unit with a Genuine Porsche master cylinder restores factory braking response, maintains system integrity, and preserves the vehicle’s original driving characteristics.

When to replace

Consider replacing the brake master cylinder if you experience:

• Soft, spongy, or sinking brake pedal

• Brake fluid leakage near the master cylinder or firewall

• Uneven or delayed braking response

• Brake warning lights related to hydraulic pressure

• Age-related wear on higher-mileage vehicles

Related reference numbers

Related, superseded, cross reference or alternative numbers for comparison.

99735591000

The product you are viewing cross references to these numbers

- Porsche Boxster 987 2.7L 2005-08/08

- Porsche Boxster 987 MKII 2.9L 2009-12

- Porsche 997 MK1 Carrera 2 3.6L 2005-08

- Porsche Cayman 2.7L 987C 2006-08

- Porsche Cayman 2.9L 987C MKII 2009-12

- Porsche Cayman S / R 3.4L 987C MKII 2009-12

OE Match quality replacement for the original Porsche unit referenced by part number 997.355.910.00 / 99735591000. The brake master cylinder converts the force applied to the brake pedal into hydraulic pressure that activates your brake calipers and slows the car. It ensures consistent braking force and modulation under daily driving or spirited use. Without a fully functioning master cylinder, braking performance can be compromised.

Fits:

Porsche 987.1 Boxster 2005 - 2008

Porsche 987.2 Boxster 2009 - 2012

Porsche 987C.1 Cayman 2006 - 2008

Porsche 987C.2 Cayman 2009 - 2012

Porsche 997.1 Carrera 2 2005 - 2008

Diagram ref no 5

Function: It houses pistons and seals that pressurize brake fluid and distribute appropriate pressure to front and rear brake circuits. When you press the brake pedal, this unit ensures the correct volume and pressure of fluid is sent through the lines for dependable stopping power.

Replacing a worn or failing master cylinder is critical for safe braking performance. Over time, internal seals deteriorate, leading to spongy pedal feel, reduced brake responsiveness, or loss of hydraulic pressure. Installing a high-quality OE Match unit restores proper brake pressure, improves pedal feel, and ensures consistent stopping power - essential for both everyday driving and performance scenarios.

When to replace

You should inspect and consider replacing your brake master cylinder if you notice any of the following:

• Brake pedal feels soft, spongy, or sinking

• Visible brake fluid leaks around the firewall or master cylinder

• Inconsistent brake pressure during stopping

• Warning lights on the dashboard indicating brake system issues

• Age-related wear or part has exceeded recommended service life

Related reference numbers

Related, superseded, cross reference or alternative numbers for comparison.

99735591000

The product you are viewing cross references to these numbers

Porsche Brake Master Cylinders | Design911 Precision Replacement Parts for Hydraulic Performance & Safety

The brake master cylinder is the heart of your Porsche’s braking system, converting pedal pressure into hydraulic force that engages the brake calipers. It ensures consistent, balanced braking across all wheels — a key factor in maintaining Porsche’s renowned control and stopping performance. When the master cylinder begins to fail, it can cause pressure loss, spongy pedals, or brake fade, making timely replacement essential for safety and precision.

At Design911, we stock a complete range of brake master cylinders, expertly engineered for exact fitment, consistent pressure delivery, and long-term durability. Each unit is crafted from high-quality materials to withstand intense hydraulic pressures and thermal cycling. Whether for road use, motorsport preparation, or classic restoration, our replacement master cylinders restore the precision and performance your Porsche was built to deliver.

What Does a Brake Master Cylinder Do?

The master cylinder plays a critical role in the hydraulic braking system, converting the mechanical pressure from your foot into fluid pressure distributed to each caliper.

Core Functions:

• Converts pedal movement into hydraulic pressure.

• Ensures even brake force distribution across all wheels.

• Maintains consistent pedal feel and braking response.

• Supports ABS and traction control systems.

• Provides safe, reliable braking performance in all conditions.

Without a properly functioning master cylinder, your Porsche’s braking system cannot maintain hydraulic balance or stopping efficiency.

Why Do Brake Master Cylinders Fail or Degrade?

Brake master cylinders endure constant hydraulic pressure and exposure to brake fluid — conditions that can lead to internal wear, leaks, or contamination over time.

Common Causes of Failure Include:

• Worn internal seals leading to pressure loss or leaks.

• Corrosion caused by moisture-contaminated brake fluid.

• Scored or pitted cylinder bores reducing seal integrity.

• Air ingress into the hydraulic system.

• Age-related degradation of rubber components.

When a master cylinder fails, it can cause reduced braking efficiency, fluid leaks, or an unresponsive pedal — all of which compromise safety and control.

Why Replace or Upgrade Your Porsche Brake Master Cylinder?

Replacing a worn or leaking master cylinder restores full hydraulic pressure and ensures reliable braking response. Design911’s precision-engineered master cylinders deliver performance and durability that meet or exceed Porsche standards.

Key Benefits:

• Restores safe and consistent braking performance.

• Prevents fluid leaks and loss of hydraulic pressure.

• Maintains proper brake balance across all wheels.

• Constructed from corrosion-resistant materials for longevity.

• Direct-fit replacements for easy installation.

• Suitable for classic and modern Porsche models.

Design911’s Porsche brake master cylinders offer exceptional reliability and performance — ensuring your Porsche stops with the same confidence and precision as it accelerates.

Highlights

• Premium Porsche brake master cylinders for performance and

restoration.

• Precision-machined for superior hydraulic control.

• Resistant to corrosion, heat, and fluid breakdown.

• Ensures firm pedal feel and consistent braking response.

• Compatible with both road and track applications.

• Designed for easy installation and long service life.