Enter your VAT number here and click Verify:

Your details have been verified. VAT number registered to:

,

.

Your order will now be zero rated for VAT purposes. We reserve the right to verify these details after your order request has been made and reinstate VAT if required.

Your VAT details were not recognised or were invalid. Your VAT number must be matched to your Billing Country as specified above. This is currently specified as . You do not need to enter the country code part of your VAT number as this has already been selected in your billing address details above.

The VAT number checking service is currently offline. Please supply your VAT details within the comments or special instructions field below and we will apply a VAT discount after placing your order request.

- Porsche 924S 2.5L 1986-87

- Porsche 924S 2.5L 1988

- Porsche 944 2.5L 8V 1982-87

- Porsche 944 2.7L 8V 1988-89

- Porsche 944S 2.5L 16V 1987-88

- Porsche 944S2 3.0L 16V 1989-91

- Porsche 944 Turbo 2.5L 8V 1985-88

- Porsche 944 Turbo 2.5L 8V 1989-91

- Porsche 968 3.0L 1992-94

- Porsche 968 Sport 3.0L 1994-95

- Porsche 968 CS 3.0L 1993-95

- Porsche 968 Turbo S 3.0L 1993-94

Fits:

Porsche 924S 1986-88 RHD Cars

Porsche 944 1982-85

Porsche 944 1985-90

Porsche 944 1985-91 (M593) cars with ABS (Bosch)

Porsche 968 1992-95

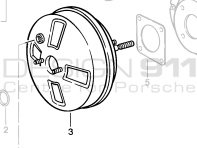

Click 'Zoom in' for large parts diagram

Diagram ref no 3.

Related reference numbers

Related, superseded, cross reference or alternative numbers for comparison.

94435502311

The product you are viewing cross references to these numbers

Brake fluid is one of the most important fluids in a car as without it, stopping the vehicle safely would be impossible. The Brake fluid transmits the force exerted by the driver on the brake pedal onto the wheel brake.

To ensure perfect operation of the brakes, the brake fluid must be changed regularly during inspection or maintenance and tested with the correct brake fluid tester.

Brake fluid should be changed every two years.

The higher the DOT class, the higher the boiling temperature and wet boiling point. Higher DOT classes tend to allow longer maintenance intervals. The DOT standards are based on the American FMVSS-116 standard of the Department of Transportation (DOT).

Boiling Point and Viscosity

Dry Boiling Point - describes the property of the sealed new brake fluid. In this state, the brake fluid is almost anhydrous (substance containing no water). The dry boiling point is usually between 240 and 280°C.

Wet Boiling Point - determines the property of the brake fluid at the end of its life cycle, at a water content of 3.5% the fluid should be replaced. This defined wet boiling point must not be undercut.

Viscosity - describes the flow rate of the brake fluid. The lower the viscosity, the faster the brake fluid flows through the brake system, and the faster the brake signals are transmitted.

Important Notes

• Brake fluid is poisonous and a hazardous waste.

• Be careful when changing. The fluid weakens paints and plastics.

• It must not come into contact with eyes or skin. Always rinse spilled liquid with water.

• Do not pour the liquid into drinking water or mix with used oil.

• The colour of the brake fluid reveals nothing about its quality.

• Brake fluid should be stored in its original packaging and in a dry, cool and well-ventilated place.

Find out about Textar product verification here

DOT 4

Having an extremely high boiling point and lower viscosity than required, it meets and greatly exceeds regulatory standards. Also suitable for vehicles with ABS.

Vapour Lock formation

This sort of habit leaves room for the Vapour Lock, the formation of vapour bubbles due to boiling of the brake fluid that replace the normal fluid and are compressed, thereby sending the brake pedal to its fill stoke (spongy pedal). The origin is incident in the porosity of the tubes that make up the braking circuit, which in time draw moisture into the fluid, drastically reducing the boiling point. The result is a reduced braking efficiency.

Brembo Premium Brake Fluid

Brembo Premium brake fluids have a higher boiling point that exceeds the standard, thus offering superior resistance to the Vapour Lock and ensuring braking efficiency even at low temperatures. With high anti-corrosion properties and resistance to oxidation, Brembo brake fluid also allows for long-term unaltered chemical/physical characteristics of the fluid in operating circuit; therefore, preserving its integrity.

Related reference numbers

Related, superseded, cross reference or alternative numbers for comparison.

L040

The product you are viewing cross references to these numbers

Brake fluid DOT 4 LV (Low Viscosity) Textar.

Textar DOT 4 LV (Low Viscosity) is especially recommended for use in hydraulic brake and clutch systems of vehicles fitted with ESP, ABS and ASR with a high boiling point and outstanding performance at very low temperatures.

DOT 4 LV (Low Viscosity)

Dry Boiling Point ≥ 260° C

Wet Boiling Point ≥ 165° C

Viscosity at -40C < 750 mm2 /s

Brake fluid is one of the most important fluids in a car as without it, stopping the vehicle safely would be impossible. The Brake fluid transmits the force exerted by the driver on the brake pedal onto the wheel brake.

To ensure perfect operation of the brakes, the brake fluid must be changed regularly during inspection or maintenance and tested with the correct brake fluid tester.

Brake fluid should be changed every two years.

The higher the DOT class, the higher the boiling temperature and wet boiling point. Higher DOT classes tend to allow longer maintenance intervals. The DOT standards are based on the American FMVSS-116 standard of the Department of Transportation (DOT).

Boiling Point and Viscosity

Dry Boiling Point - describes the property of the sealed new brake fluid. In this state, the brake fluid is almost anhydrous (substance containing no water). The dry boiling point is usually between 240 and 280°C.

Wet Boiling Point - determines the property of the brake fluid at the end of its life cycle, at a water content of 3.5% the fluid should be replaced. This defined wet boiling point must not be undercut. <

Viscosity - describes the flow rate of the brake fluid. The lower the viscosity, the faster the brake fluid flows through the brake system, and the faster the brake signals are transmitted.

Important Notes

• Brake fluid is poisonous and a hazardous waste.

• Be careful when changing. The fluid weakens paints and plastics.

• It must not come into contact with eyes or skin. Always rinse spilled liquid with water.

• Do not pour the liquid into drinking water or mix with used oil.

• The colour of the brake fluid reveals nothing about its quality.

• Brake fluid should be stored in its original packaging and in a dry, cool and well-ventilated place.

Find out about Textar product verification here

Related reference numbers

Related, superseded, cross reference or alternative numbers for comparison.

95006

The product you are viewing cross references to these numbers

Brake fluid is one of the most important fluids in a car as without it, stopping the vehicle safely would be impossible. The Brake fluid transmits the force exerted by the driver on the brake pedal onto the wheel brake.

To ensure perfect operation of the brakes, the brake fluid must be changed regularly during inspection or maintenance and tested with the correct brake fluid tester.

Brake fluid should be changed every two years.

The higher the DOT class, the higher the boiling temperature and wet boiling point. Higher DOT classes tend to allow longer maintenance intervals. The DOT standards are based on the American FMVSS-116 standard of the Department of Transportation (DOT).

Boiling Point and Viscosity

Dry Boiling Point - describes the property of the sealed new brake fluid. In this state, the brake fluid is almost anhydrous (substance containing no water). The dry boiling point is usually between 240 and 280°C.

Wet Boiling Point - determines the property of the brake fluid at the end of its life cycle, at a water content of 3.5% the fluid should be replaced. This defined wet boiling point must not be undercut.

Viscosity - describes the flow rate of the brake fluid. The lower the viscosity, the faster the brake fluid flows through the brake system, and the faster the brake signals are transmitted.

Important Notes

• Brake fluid is poisonous and a hazardous waste.

• Be careful when changing. The fluid weakens paints and plastics.

• It must not come into contact with eyes or skin. Always rinse spilled liquid with water.

• Do not pour the liquid into drinking water or mix with used oil.

• The colour of the brake fluid reveals nothing about its quality.

• Brake fluid should be stored in its original packaging and in a dry, cool and well-ventilated place.

Find out about Textar product verification here

Related reference numbers

Related, superseded, cross reference or alternative numbers for comparison.

95002

The product you are viewing cross references to these numbers

Porsche Brake Servo / Booster | Design911 Precision Replacement Parts for Enhanced Braking Power & Control

The brake servo, also known as the brake booster, is a crucial component in your Porsche’s braking system. It uses engine vacuum or hydraulic pressure to amplify the force applied to the brake pedal, making braking smoother, more responsive, and less physically demanding. A properly functioning servo ensures effortless braking and preserves Porsche’s signature pedal feel. When it begins to fail, pedal pressure increases, and braking performance declines — making replacement essential for safety and comfort.

At Design911, we supply a wide range of brake servos and boosters, engineered for exact fitment and long-term reliability. Each unit is manufactured using premium materials and advanced sealing technology to deliver consistent vacuum assistance and hydraulic integrity. Whether for road use, restoration, or performance upgrades, our brake servos ensure the precision braking your Porsche deserves.

What Does a Brake Servo / Booster Do?

The brake servo multiplies the force from the brake pedal before transmitting it to the master cylinder, reducing the effort required to slow the vehicle.

Core Functions:

• Amplifies pedal force for enhanced braking efficiency.

• Provides smooth and responsive brake pedal feel.

• Supports consistent braking performance across varying speeds.

• Helps maintain driver comfort and control during deceleration.

• Works in conjunction with ABS and stability systems for balance and safety.

An efficient servo system ensures your Porsche brakes with the precision, strength, and responsiveness it was engineered for.

Why Do Brake Servos / Boosters Fail or Degrade?

Over time, servos are exposed to vacuum pressure, moisture, and mechanical wear that can affect their internal seals, diaphragm, or valves.

Common Causes of Failure Include:

• Vacuum leaks caused by worn or cracked diaphragms.

• Corrosion or moisture ingress affecting internal components.

• Broken check valves or damaged seals.

• Reduced vacuum supply due to engine issues.

• Age-related wear in the booster mechanism.

When the servo fails, drivers may experience a hard brake pedal, increased stopping distance, or inconsistent braking assistance — compromising safety and performance.

Why Replace or Upgrade Your Porsche Brake Servo / Booster?

Replacing a failing or inefficient brake servo restores correct braking assistance and ensures safe, predictable braking response. Design911’s precision-engineered servos are designed for durability, direct fitment, and compatibility across Porsche models.

Key Benefits:

• Restores proper brake assistance and pedal feel.

• Improves braking comfort and control.

• Constructed with corrosion-resistant materials for longevity.

• Engineered for consistent vacuum and hydraulic performance.

• Direct-fit design ensures easy installation.

• Suitable for classic and modern Porsche vehicles.

Design911’s Porsche brake servos and boosters deliver the confidence and reliability required for every driving situation — from city traffic to high-speed performance.

Highlights

• Premium Porsche brake servos and boosters.

• Precision-engineered for hydraulic and vacuum efficiency.

• Restores effortless braking power and smooth pedal response.

• Corrosion-resistant construction for long service life.

• Ideal for performance, restoration, or maintenance applications.

• Compatible with a wide range of Porsche models.